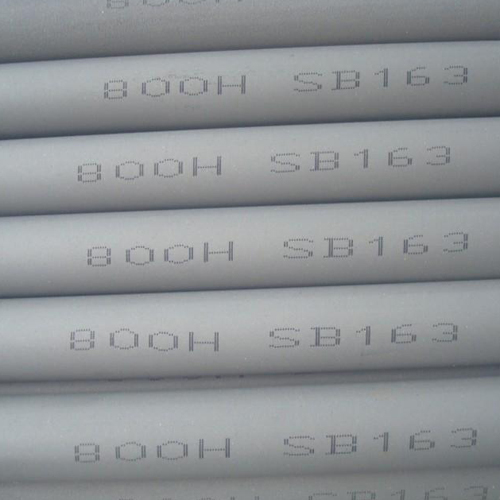

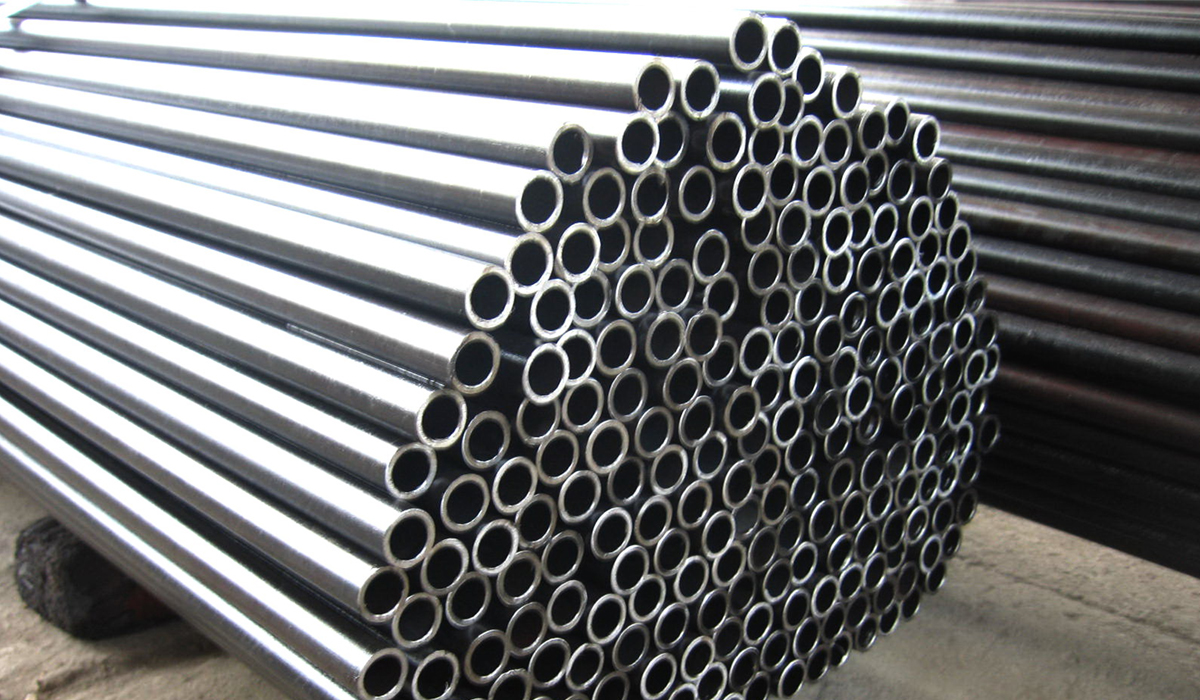

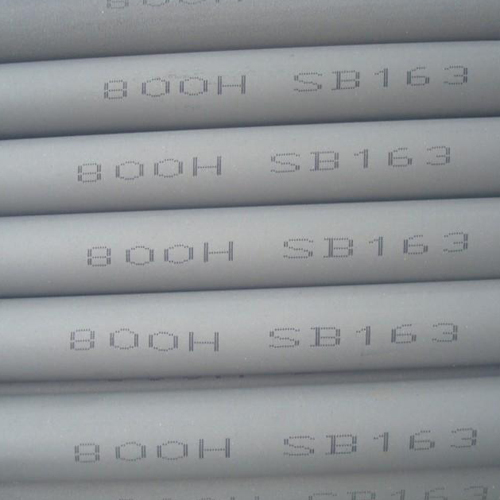

● Material: Nickel alloy 600, 625, 718, 800, 825, Hastelloy C22, C276, Monel 400, etc.

● Standard: ASTM B163, B165, B167, B407, B444, B622, etc.

● Package: Wooden case or woven bag packaging.

● Delivery time: as required, usually within 2 months.

● Payment terms: T/T or L/C available.

● Shipping terms: FOB or CFR available.

Request A Quote